English ![]()

No. 7, Tianyang 6th Road, Dongfang Community, Songgang Street, Bao'an District, Shenzhen, Guangdong, China(518100)

| Availability: | |

|---|---|

| Quantity: | |

The optoelectronics industry requires components with exceptional dimensional stability, thermal management properties, and electromagnetic shielding capabilities. Die casting has become an indispensable manufacturing solution for producing high-performance housings, heat sinks, and structural elements in LED lighting, laser systems, fiber optics, and imaging equipment. This process enables the mass production of complex optoelectronic components with micron-level precision while maintaining excellent mechanical and thermal properties.

Why Die Casting is Ideal for Optoelectronics?

Optoelectronic devices demand:

✔ Precision dimensional control for optical alignment

✔ Superior heat dissipation for high-power applications

✔ EMI/RFI shielding for signal-sensitive components

✔ Corrosion resistance for harsh environments

✔ Lightweight designs for portable devices

Die casting meets these requirements while offering cost advantages over machining and plastic injection molding.

Key Materials for Optoelectronic Die Casting

1. Aluminum Alloys (A380, A356)

Advantages: Excellent thermal conductivity (≈120 W/m·K), lightweight

Applications: LED heat sinks, laser diode housings, optical mounts

2. Zinc Alloys (ZA-8, Zamak 5)

Advantages: Superior EMI shielding (>100 dB attenuation), fine detail replication

Applications: Sensor enclosures, connector housings, camera bodies

3. Magnesium Alloys (AZ91D, AM60B)

Advantages: Lowest density (1.8 g/cm³), good damping characteristics

Applications: Portable device frames, vibration-sensitive optical platforms

5 Critical Advantages for Optoelectronic Applications

① Thermal Management Excellence

Aluminum die casts achieve thermal conductivity 5-8× higher than plastics

Integrated cooling fins can reduce junction temperatures by 15-20°C

Coefficient of thermal expansion (CTE) matching critical for optical alignment

② Precision Optical Alignment Features

Holds ±0.025mm positional tolerances for lens mounts

Surface finishes down to 0.8μm Ra achievable without machining

Complex internal light baffles cast-in-place

③ Electromagnetic Protection

Zinc alloys provide complete Faraday cage protection

Seamless enclosures eliminate EMI leakage points

Grounding features cast directly into components

④ Environmental Durability

Anodized aluminum resists UV degradation in outdoor lighting

Salt spray resistance exceeds 1000 hours (ASTM B117)

Hermetic seals possible with proper gasket design

⑤ Cost-Effective Complex Geometries

Combines multiple parts into single castings (e.g., heat sink + housing)

Thin-wall capabilities down to 0.5mm for weight reduction

Post-casting processes reduced by 60-80% versus machining

Major Optoelectronic Applications

| Die Cast Components | Benefits | |

| LED Lighting Systems | Heat sinks, reflector housings, driver enclosures | 30% better thermal performance than extruded aluminum |

| Laser & Fiber Optic Equipment | Diode mounts, collimator bodies, alignment stages | Vibration damping critical for micron-level stability |

| Imaging & Sensing Devices | Camera bodies, IR sensor housings, LIDAR mounts | EMI shielding preserves signal integrity |

| Solar Energy Systems | Inverter housings, tracking system gears | Weather resistance for 25+ year service life |

| Emerging Innovations | Die cast frames with overmolded optical elements Microchannel heat exchangers cast directly into components | New die coatings enabling reflector-grade finishes |

Die casting provides optoelectronic manufacturers with unparalleled capabilities to produce precision components that meet the demanding requirements of light-based technologies. From ensuring perfect optical alignment to managing heat in high-power applications, die cast components continue to enable advancements in lighting, communications, and sensing technologies. As optoelectronic devices evolve toward higher power densities and smaller form factors, die casting will remain at the forefront of manufacturing solutions for this critical industry.

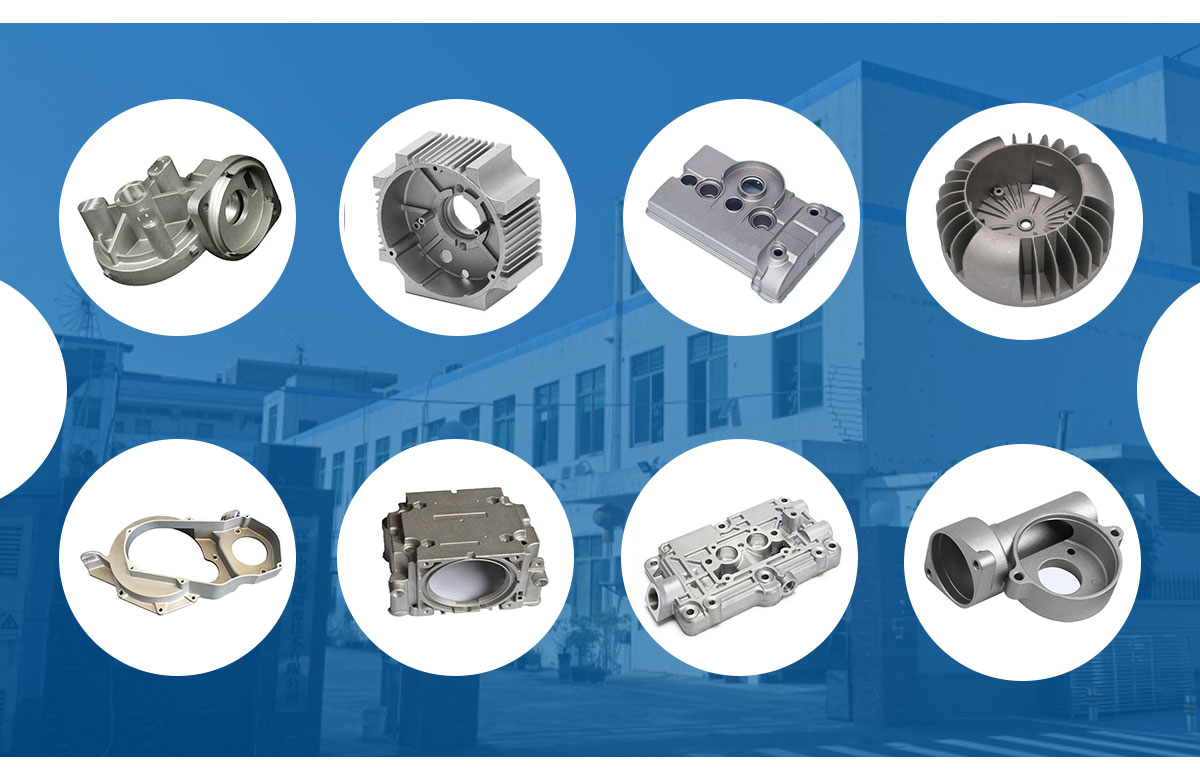

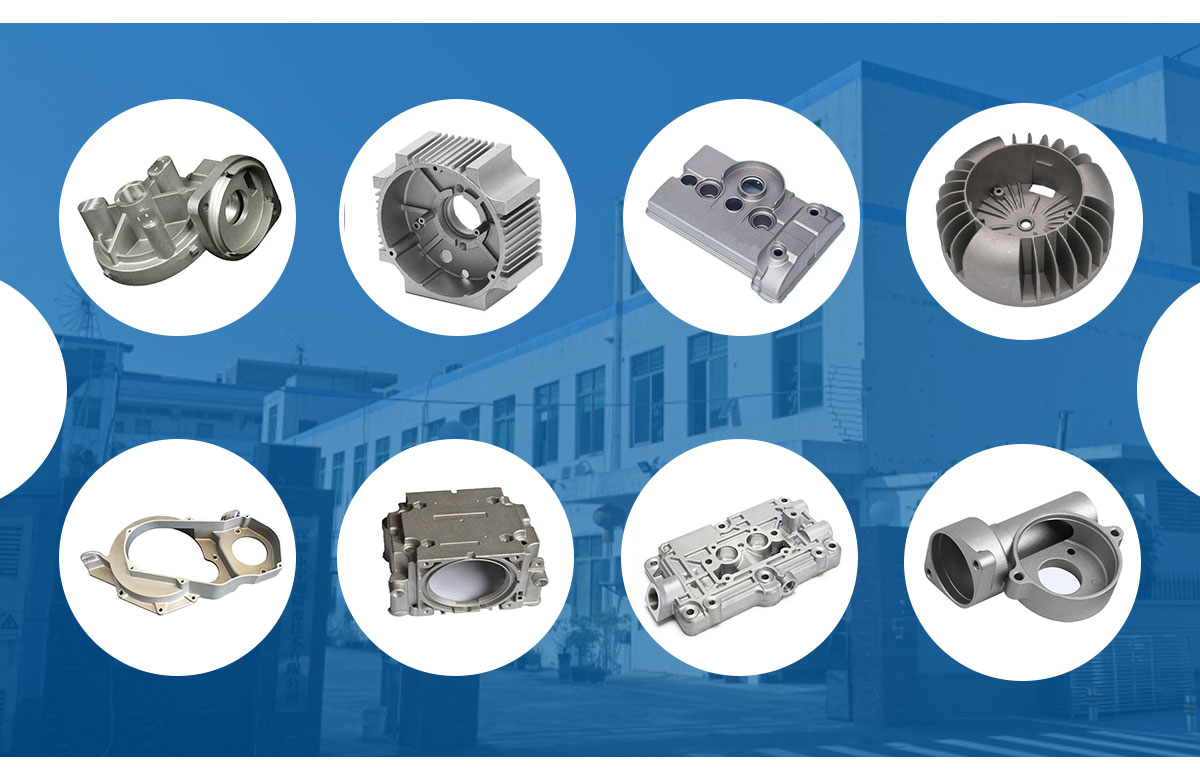

Representative optoelectronic die cast components would include: LED heat sink assemblies, laser housing units, fiber optic connector bodies, thermal imaging camera chassis, solar inverter enclosures, and precision optical mounting platforms.

Would you like detailed comparisons between die casting and alternative manufacturing methods for specific optoelectronic components?

The optoelectronics industry requires components with exceptional dimensional stability, thermal management properties, and electromagnetic shielding capabilities. Die casting has become an indispensable manufacturing solution for producing high-performance housings, heat sinks, and structural elements in LED lighting, laser systems, fiber optics, and imaging equipment. This process enables the mass production of complex optoelectronic components with micron-level precision while maintaining excellent mechanical and thermal properties.

Why Die Casting is Ideal for Optoelectronics?

Optoelectronic devices demand:

✔ Precision dimensional control for optical alignment

✔ Superior heat dissipation for high-power applications

✔ EMI/RFI shielding for signal-sensitive components

✔ Corrosion resistance for harsh environments

✔ Lightweight designs for portable devices

Die casting meets these requirements while offering cost advantages over machining and plastic injection molding.

Key Materials for Optoelectronic Die Casting

1. Aluminum Alloys (A380, A356)

Advantages: Excellent thermal conductivity (≈120 W/m·K), lightweight

Applications: LED heat sinks, laser diode housings, optical mounts

2. Zinc Alloys (ZA-8, Zamak 5)

Advantages: Superior EMI shielding (>100 dB attenuation), fine detail replication

Applications: Sensor enclosures, connector housings, camera bodies

3. Magnesium Alloys (AZ91D, AM60B)

Advantages: Lowest density (1.8 g/cm³), good damping characteristics

Applications: Portable device frames, vibration-sensitive optical platforms

5 Critical Advantages for Optoelectronic Applications

① Thermal Management Excellence

Aluminum die casts achieve thermal conductivity 5-8× higher than plastics

Integrated cooling fins can reduce junction temperatures by 15-20°C

Coefficient of thermal expansion (CTE) matching critical for optical alignment

② Precision Optical Alignment Features

Holds ±0.025mm positional tolerances for lens mounts

Surface finishes down to 0.8μm Ra achievable without machining

Complex internal light baffles cast-in-place

③ Electromagnetic Protection

Zinc alloys provide complete Faraday cage protection

Seamless enclosures eliminate EMI leakage points

Grounding features cast directly into components

④ Environmental Durability

Anodized aluminum resists UV degradation in outdoor lighting

Salt spray resistance exceeds 1000 hours (ASTM B117)

Hermetic seals possible with proper gasket design

⑤ Cost-Effective Complex Geometries

Combines multiple parts into single castings (e.g., heat sink + housing)

Thin-wall capabilities down to 0.5mm for weight reduction

Post-casting processes reduced by 60-80% versus machining

Major Optoelectronic Applications

| Die Cast Components | Benefits | |

| LED Lighting Systems | Heat sinks, reflector housings, driver enclosures | 30% better thermal performance than extruded aluminum |

| Laser & Fiber Optic Equipment | Diode mounts, collimator bodies, alignment stages | Vibration damping critical for micron-level stability |

| Imaging & Sensing Devices | Camera bodies, IR sensor housings, LIDAR mounts | EMI shielding preserves signal integrity |

| Solar Energy Systems | Inverter housings, tracking system gears | Weather resistance for 25+ year service life |

| Emerging Innovations | Die cast frames with overmolded optical elements Microchannel heat exchangers cast directly into components | New die coatings enabling reflector-grade finishes |

Die casting provides optoelectronic manufacturers with unparalleled capabilities to produce precision components that meet the demanding requirements of light-based technologies. From ensuring perfect optical alignment to managing heat in high-power applications, die cast components continue to enable advancements in lighting, communications, and sensing technologies. As optoelectronic devices evolve toward higher power densities and smaller form factors, die casting will remain at the forefront of manufacturing solutions for this critical industry.

Representative optoelectronic die cast components would include: LED heat sink assemblies, laser housing units, fiber optic connector bodies, thermal imaging camera chassis, solar inverter enclosures, and precision optical mounting platforms.

Would you like detailed comparisons between die casting and alternative manufacturing methods for specific optoelectronic components?