English ![]()

No. 7, Tianyang 6th Road, Dongfang Community, Songgang Street, Bao'an District, Shenzhen, Guangdong, China(518100)

| Availability: | |

|---|---|

| Quantity: | |

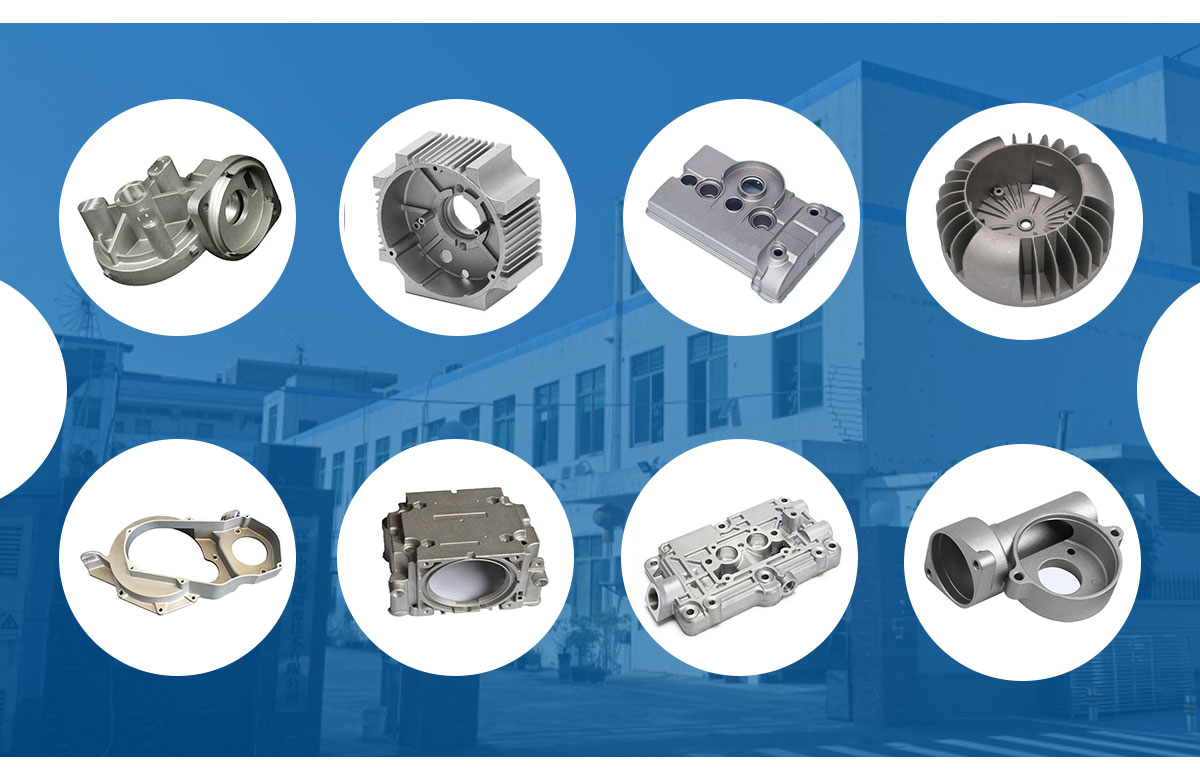

Die casting is a cornerstone of modern automotive manufacturing, enabling the production of high-strength, lightweight, and complex metal components with exceptional precision. The process involves injecting molten metal—typically aluminum, magnesium, or zinc alloys—into a steel mold under high pressure. This method is widely used in the automotive industry to produce everything from engine parts to structural components, offering significant advantages in performance, cost, and efficiency.

Why Die Casting is Essential in Automotive Production?

Automotive manufacturers rely on die casting for:

✔ Lightweighting – Improving fuel efficiency and EV battery range

✔ High Strength & Durability – Ensuring safety and longevity

✔ Cost Efficiency – Reducing machining and assembly costs

✔ Design Flexibility – Enabling complex, integrated geometries

Common Automotive Die Casting Materials

1. Aluminum Alloys (e.g., A380, A383, ADC12)

Advantages: Lightweight, corrosion-resistant, excellent thermal conductivity

Applications: Engine blocks, transmission cases, suspension components

2. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Lightest structural metal (35% lighter than aluminum), good shock absorption

Applications: Steering wheels, seat frames, instrument panels

3. Zinc Alloys (e.g., ZA-8, Zamak 3)

Advantages: High dimensional stability, excellent surface finish

Applications: Door handles, brackets, electrical connectors

Key Advantages of Die Casting in Automotive Manufacturing

✅ Weight Reduction – Critical for fuel efficiency and electric vehicle (EV) performance.

✅ High Production Speed – Ideal for mass production of millions of parts.

✅ Superior Strength & Rigidity – Ensures crash safety and durability.

✅ Near-Net-Shape Precision – Minimizes machining and material waste.

✅ Corrosion Resistance – Extends component lifespan in harsh conditions.

✅ Cost-Effective for High Volumes – Lower per-unit cost compared to machining or forging.

Automotive Applications of Die Casting

1. Powertrain Components

Examples: Engine blocks, transmission housings, oil pans

Benefits: Heat dissipation, reduced weight, high structural integrity

2. Structural & Chassis Parts

Examples: Subframes, suspension arms, crossmembers

Benefits: Lightweight yet strong, improves vehicle handling

3. Body & Interior Components

Examples: Door frames, seat brackets, dashboard supports

Benefits: Enhances safety while reducing overall vehicle weight

4. Electrical & EV Components

Examples: Battery housings, motor enclosures, charging connectors

Benefits: Lightweighting for extended EV range, EMI shielding

Future Trends in Automotive Die Casting

Gigacasting–Tesla and other automakers are using massive die-casting machines to produce entire vehicle underbodies in one piece, reducing parts and assembly time.

High-Pressure Vacuum Die Casting – Improves part density and reduces porosity for critical safety components.

Sustainable Materials – Increased use of recycled aluminum alloys to reduce environmental impact.

Die casting is a vital technology in the automotive industry, enabling the production of lightweight, durable, and cost-effective components. As the industry shifts toward electric vehicles and stricter emissions standards, die casting will continue to play a pivotal role in vehicle design and manufacturing.

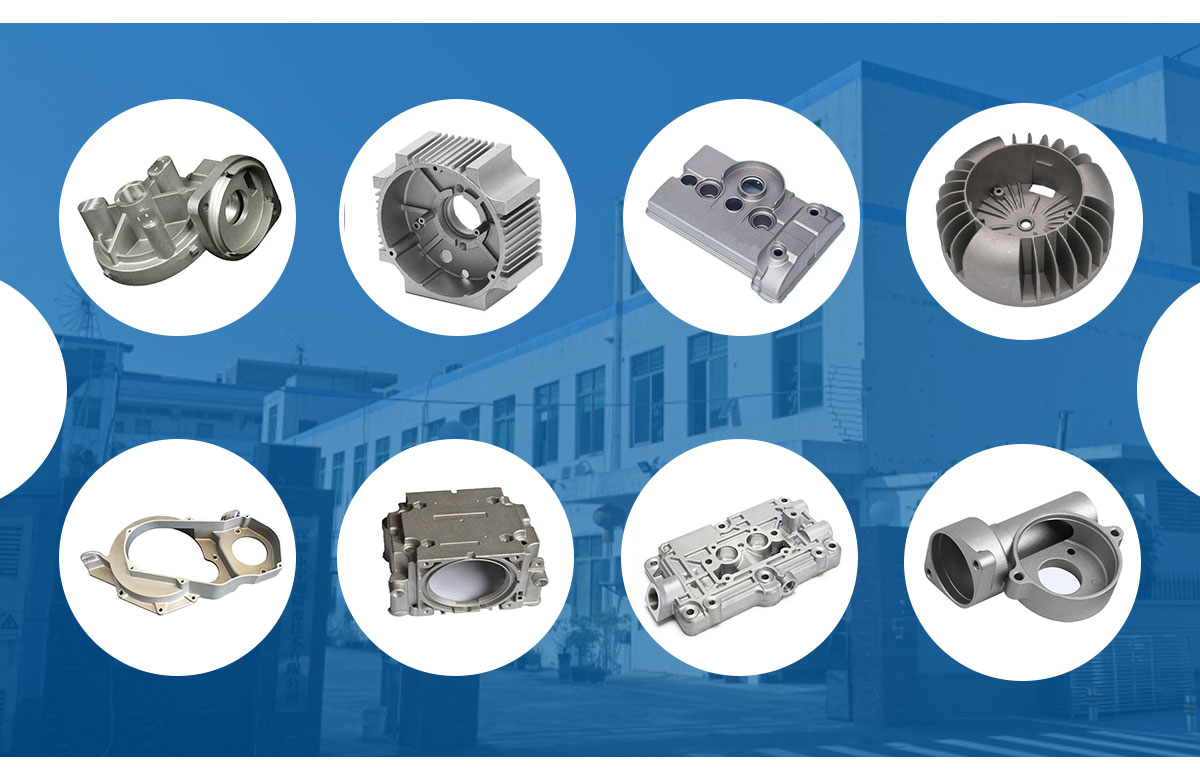

Die casting is a cornerstone of modern automotive manufacturing, enabling the production of high-strength, lightweight, and complex metal components with exceptional precision. The process involves injecting molten metal—typically aluminum, magnesium, or zinc alloys—into a steel mold under high pressure. This method is widely used in the automotive industry to produce everything from engine parts to structural components, offering significant advantages in performance, cost, and efficiency.

Why Die Casting is Essential in Automotive Production?

Automotive manufacturers rely on die casting for:

✔ Lightweighting – Improving fuel efficiency and EV battery range

✔ High Strength & Durability – Ensuring safety and longevity

✔ Cost Efficiency – Reducing machining and assembly costs

✔ Design Flexibility – Enabling complex, integrated geometries

Common Automotive Die Casting Materials

1. Aluminum Alloys (e.g., A380, A383, ADC12)

Advantages: Lightweight, corrosion-resistant, excellent thermal conductivity

Applications: Engine blocks, transmission cases, suspension components

2. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Lightest structural metal (35% lighter than aluminum), good shock absorption

Applications: Steering wheels, seat frames, instrument panels

3. Zinc Alloys (e.g., ZA-8, Zamak 3)

Advantages: High dimensional stability, excellent surface finish

Applications: Door handles, brackets, electrical connectors

Key Advantages of Die Casting in Automotive Manufacturing

✅ Weight Reduction – Critical for fuel efficiency and electric vehicle (EV) performance.

✅ High Production Speed – Ideal for mass production of millions of parts.

✅ Superior Strength & Rigidity – Ensures crash safety and durability.

✅ Near-Net-Shape Precision – Minimizes machining and material waste.

✅ Corrosion Resistance – Extends component lifespan in harsh conditions.

✅ Cost-Effective for High Volumes – Lower per-unit cost compared to machining or forging.

Automotive Applications of Die Casting

1. Powertrain Components

Examples: Engine blocks, transmission housings, oil pans

Benefits: Heat dissipation, reduced weight, high structural integrity

2. Structural & Chassis Parts

Examples: Subframes, suspension arms, crossmembers

Benefits: Lightweight yet strong, improves vehicle handling

3. Body & Interior Components

Examples: Door frames, seat brackets, dashboard supports

Benefits: Enhances safety while reducing overall vehicle weight

4. Electrical & EV Components

Examples: Battery housings, motor enclosures, charging connectors

Benefits: Lightweighting for extended EV range, EMI shielding

Future Trends in Automotive Die Casting

Gigacasting–Tesla and other automakers are using massive die-casting machines to produce entire vehicle underbodies in one piece, reducing parts and assembly time.

High-Pressure Vacuum Die Casting – Improves part density and reduces porosity for critical safety components.

Sustainable Materials – Increased use of recycled aluminum alloys to reduce environmental impact.

Die casting is a vital technology in the automotive industry, enabling the production of lightweight, durable, and cost-effective components. As the industry shifts toward electric vehicles and stricter emissions standards, die casting will continue to play a pivotal role in vehicle design and manufacturing.