English ![]()

No. 7, Tianyang 6th Road, Dongfang Community, Songgang Street, Bao'an District, Shenzhen, Guangdong, China(518100)

| Availability: | |

|---|---|

| Quantity: | |

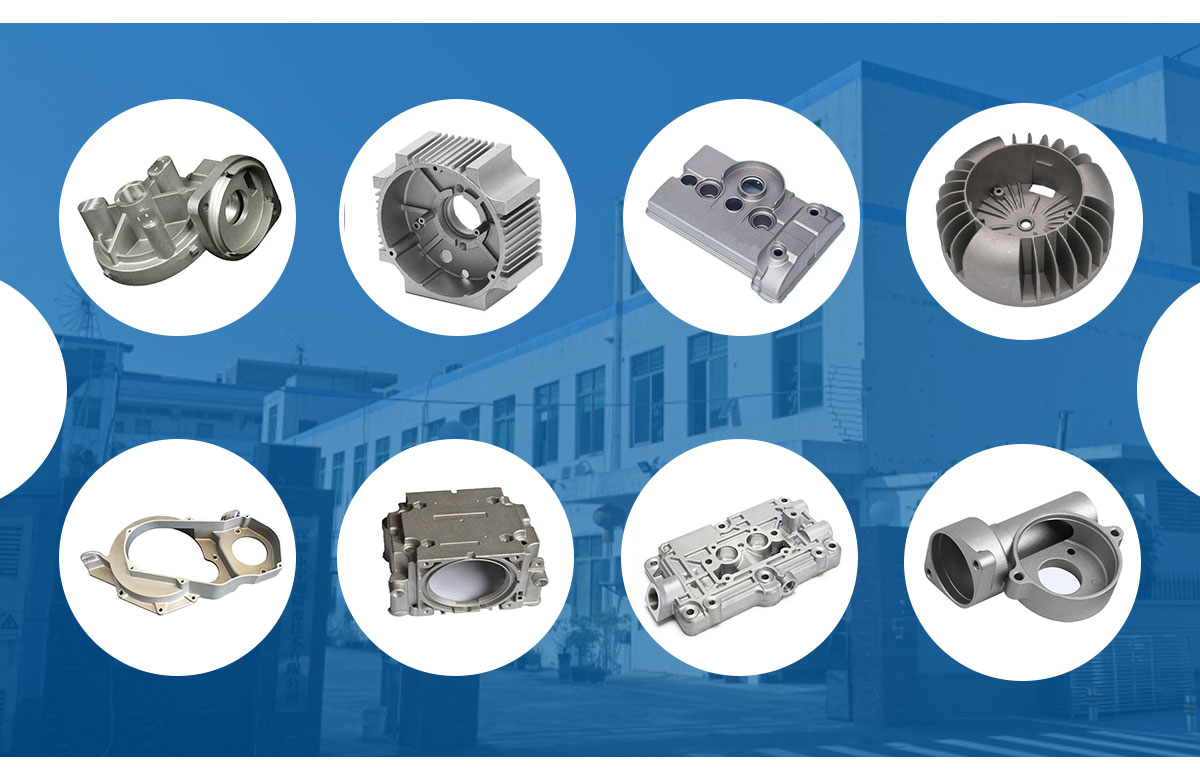

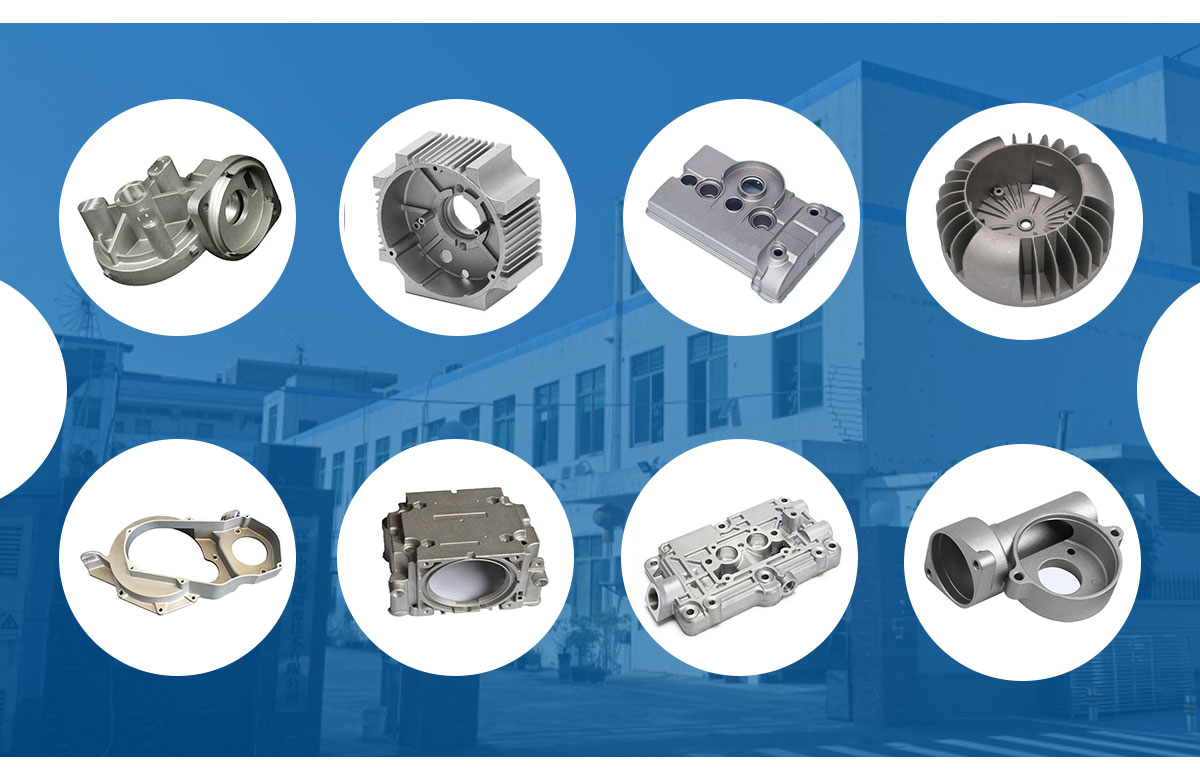

The robotics industry demands components that combine lightweight properties with exceptional strength, precision, and durability. Die casting has emerged as a critical manufacturing process for producing high-performance robotic parts, from industrial robotic arms to collaborative robots (cobots) and service robots. By injecting molten metal—typically aluminum, magnesium, or zinc alloys—into precision molds under high pressure, die casting enables the production of complex, high-tolerance components that meet the rigorous demands of robotic applications.

Why Die Casting is Essential for Robotics?

Robotic systems require:

✔ High Strength-to-Weight Ratio – For energy efficiency and payload optimization

✔ Precision Engineering – To ensure smooth motion and repeatability

✔ Durability – For long operational life in industrial environments

✔ Thermal & Electrical Conductivity – For motor and electronic component performance

✔ Cost Efficiency – To enable scalable production

Die casting meets these needs while allowing for intricate designs that reduce assembly complexity.

Key Materials for Robotic Die Casting

1. Aluminum Alloys (A380, A356, ADC12)

Advantages: Lightweight, excellent stiffness, good thermal dissipation

Applications: Robotic arm links, motor housings, structural frames

2. Magnesium Alloys (AZ91D, AM60B)

Advantages: 35% lighter than aluminum, superior vibration damping

Applications: Cobot joints, drone-based robot chassis, wearable exoskeletons

3. Zinc Alloys (Zamak 3, Zamak 5, ZA-8)

Advantages: High dimensional stability, smooth surfaces, EMI shielding

Applications: Gearbox housings, sensor mounts, connector components

5 Major Advantages of Die Casting for Robotics

① Lightweight Yet Strong Components

Magnesium die casts reduce weight by up to 50% vs. steel while maintaining structural integrity.

Aluminum robotic arms improve energy efficiency without sacrificing load capacity.

② High Precision & Repeatability

Holds tight tolerances (±0.05mm) for gear meshing and bearing fits.

Ensures smooth articulation in robotic joints and reducers.

③ Enhanced Durability for Harsh Environments

Resists wear in high-cycle applications (e.g., industrial robot joints).

Corrosion-resistant coatings extend lifespan in humid or chemical-exposed settings.

④ Integrated Design Complexity

Combines multiple parts into single castings (e.g., motor housing + heat sink).

Allows internal cooling channels for motor and drive thermal management.

⑤ Cost-Effective Mass Production

Lower per-unit cost than CNC machining for high-volume orders.

Reduces post-processing (e.g., milling, drilling) by 40-60%.

Critical Robotic Applications

| Types of robots | Components: | Benefits: |

Industrial Robots | Arm segments, end-effector mounts, base frames | High stiffness for precise repeatability (±0.02mm) |

| Collaborative Robots (Cobots) | Lightweight links, force-torque sensor housings | Safe human-robot interaction due to magnesium’s impact absorption |

| Service & Medical Robots | Surgical robot joints, disinfection robot chassis | Biocompatible coatings for medical-grade use |

| Mobile & AGV Robots | Drive system housings, lidar mounts | Vibration damping for stable navigation |

Future Trends in Robotic Die Casting

Smart Molds: IoT-enabled dies for real-time quality monitoring

Hybrid Manufacturing: Combining die casting with 3D-printed functional inserts

New Alloys: High-strength aluminum-magnesium composites for aerospace-grade robotics

Die casting is revolutionizing robotics by enabling lightweight, high-strength, and cost-effective components that meet the industry’s evolving demands. As robots become more advanced—requiring greater precision, agility, and durability—die casting will remain a cornerstone manufacturing method, supporting innovations from factory automation to surgical robotics and beyond.

(Key die-cast robotic components include: robotic arm linkages, harmonic drive housings, servo motor casings, gripper bodies, and mobile robot chassis.)

Would you like specific case studies comparing die casting vs. additive manufacturing for robotic components?

The robotics industry demands components that combine lightweight properties with exceptional strength, precision, and durability. Die casting has emerged as a critical manufacturing process for producing high-performance robotic parts, from industrial robotic arms to collaborative robots (cobots) and service robots. By injecting molten metal—typically aluminum, magnesium, or zinc alloys—into precision molds under high pressure, die casting enables the production of complex, high-tolerance components that meet the rigorous demands of robotic applications.

Why Die Casting is Essential for Robotics?

Robotic systems require:

✔ High Strength-to-Weight Ratio – For energy efficiency and payload optimization

✔ Precision Engineering – To ensure smooth motion and repeatability

✔ Durability – For long operational life in industrial environments

✔ Thermal & Electrical Conductivity – For motor and electronic component performance

✔ Cost Efficiency – To enable scalable production

Die casting meets these needs while allowing for intricate designs that reduce assembly complexity.

Key Materials for Robotic Die Casting

1. Aluminum Alloys (A380, A356, ADC12)

Advantages: Lightweight, excellent stiffness, good thermal dissipation

Applications: Robotic arm links, motor housings, structural frames

2. Magnesium Alloys (AZ91D, AM60B)

Advantages: 35% lighter than aluminum, superior vibration damping

Applications: Cobot joints, drone-based robot chassis, wearable exoskeletons

3. Zinc Alloys (Zamak 3, Zamak 5, ZA-8)

Advantages: High dimensional stability, smooth surfaces, EMI shielding

Applications: Gearbox housings, sensor mounts, connector components

5 Major Advantages of Die Casting for Robotics

① Lightweight Yet Strong Components

Magnesium die casts reduce weight by up to 50% vs. steel while maintaining structural integrity.

Aluminum robotic arms improve energy efficiency without sacrificing load capacity.

② High Precision & Repeatability

Holds tight tolerances (±0.05mm) for gear meshing and bearing fits.

Ensures smooth articulation in robotic joints and reducers.

③ Enhanced Durability for Harsh Environments

Resists wear in high-cycle applications (e.g., industrial robot joints).

Corrosion-resistant coatings extend lifespan in humid or chemical-exposed settings.

④ Integrated Design Complexity

Combines multiple parts into single castings (e.g., motor housing + heat sink).

Allows internal cooling channels for motor and drive thermal management.

⑤ Cost-Effective Mass Production

Lower per-unit cost than CNC machining for high-volume orders.

Reduces post-processing (e.g., milling, drilling) by 40-60%.

Critical Robotic Applications

| Types of robots | Components: | Benefits: |

Industrial Robots | Arm segments, end-effector mounts, base frames | High stiffness for precise repeatability (±0.02mm) |

| Collaborative Robots (Cobots) | Lightweight links, force-torque sensor housings | Safe human-robot interaction due to magnesium’s impact absorption |

| Service & Medical Robots | Surgical robot joints, disinfection robot chassis | Biocompatible coatings for medical-grade use |

| Mobile & AGV Robots | Drive system housings, lidar mounts | Vibration damping for stable navigation |

Future Trends in Robotic Die Casting

Smart Molds: IoT-enabled dies for real-time quality monitoring

Hybrid Manufacturing: Combining die casting with 3D-printed functional inserts

New Alloys: High-strength aluminum-magnesium composites for aerospace-grade robotics

Die casting is revolutionizing robotics by enabling lightweight, high-strength, and cost-effective components that meet the industry’s evolving demands. As robots become more advanced—requiring greater precision, agility, and durability—die casting will remain a cornerstone manufacturing method, supporting innovations from factory automation to surgical robotics and beyond.

(Key die-cast robotic components include: robotic arm linkages, harmonic drive housings, servo motor casings, gripper bodies, and mobile robot chassis.)

Would you like specific case studies comparing die casting vs. additive manufacturing for robotic components?