English ![]()

No. 7, Tianyang 6th Road, Dongfang Community, Songgang Street, Bao'an District, Shenzhen, Guangdong, China(518100)

| Availability: | |

|---|---|

| Quantity: | |

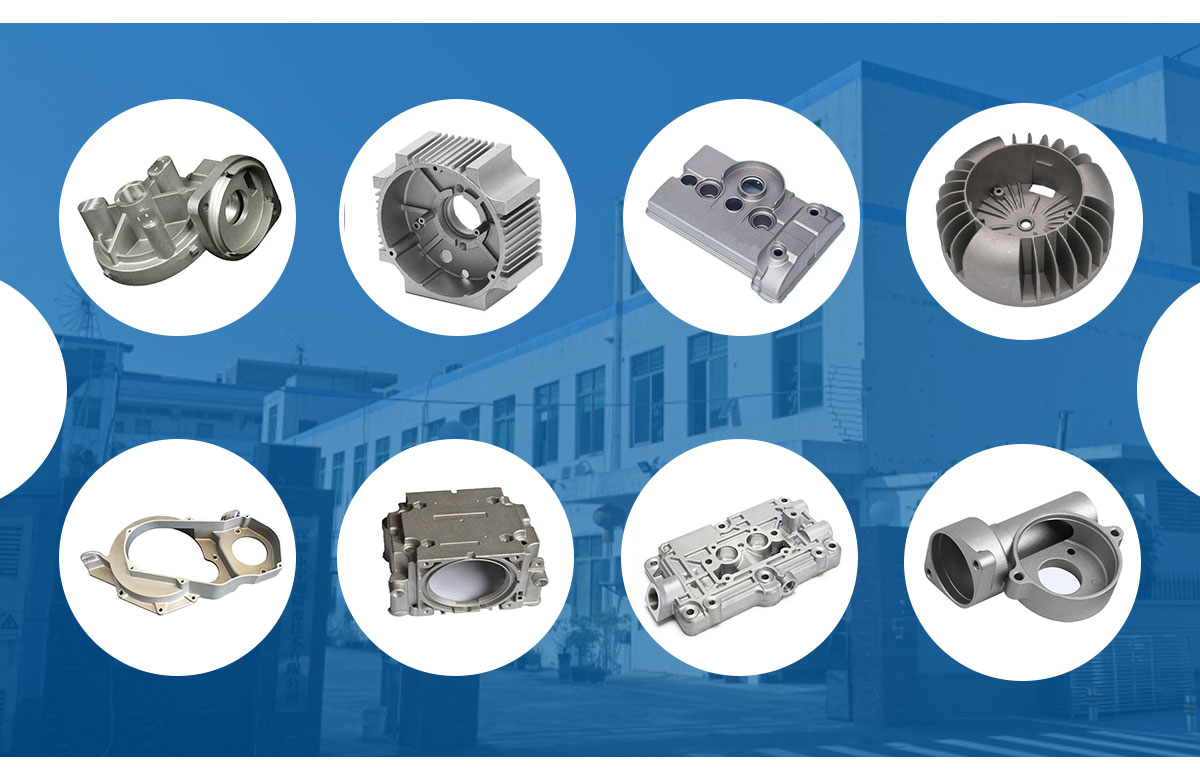

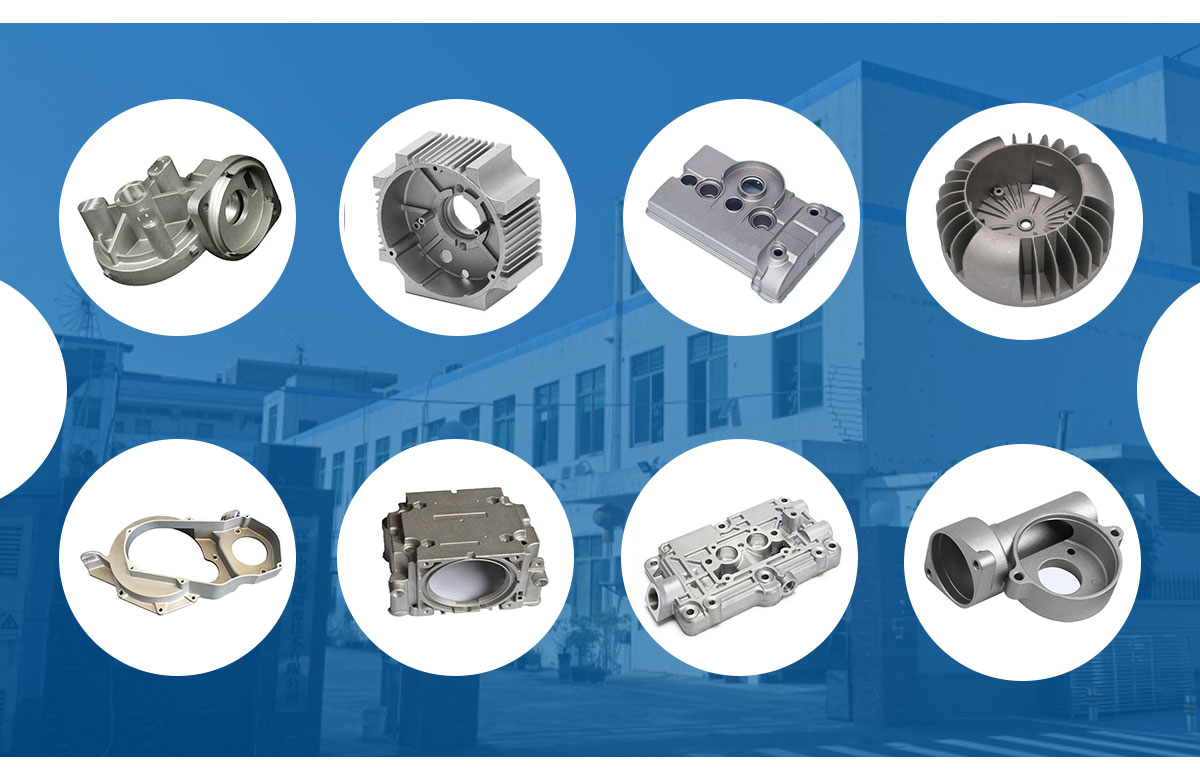

Die casting is an advanced manufacturing process increasingly used in the medical industry to produce high-precision, sterile, and durable components. The process involves injecting molten metal—typically aluminum, zinc, or magnesium alloys—into precision-engineered steel molds under high pressure. This method ensures exceptional accuracy, smooth surface finishes, and structural integrity, making it ideal for medical instruments, implants, and diagnostic equipment.

Why Die Casting is Used in Medical Applications?

Medical devices require:

✔ High Precision – Tight tolerances for reliable performance

✔ Biocompatibility – Safe for contact with human tissue

✔ Sterilizability – Resistance to autoclaving and chemical cleaning

✔ Durability – Long-lasting performance in demanding environments

Die casting meets these demands while offering cost-efficiency and scalability for mass production.

Common Medical Die Casting Materials

1. Aluminum Alloys (e.g., A380, A360)

Advantages: Lightweight, corrosion-resistant, excellent thermal conductivity

Applications: Surgical instruments, imaging equipment housings, prosthetics

2. Zinc Alloys (e.g., Zamak 3, Zamak 5)

Advantages: High dimensional stability, smooth surface finish, biocompatibility

Applications: Dental tools, syringe components, orthopedic devices

3. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Ultra-lightweight, excellent strength-to-weight ratio, MRI compatibility

Applications: Portable medical devices, surgical robots, implantable components

Key Advantages of Die Casting in Medical Manufacturing

✅ Superior Precision – Produces complex geometries with tight tolerances (±0.005 inches).

✅ Smooth Surface Finish – Reduces bacterial adhesion and simplifies sterilization.

✅ Biocompatibility – Suitable for implants and devices in prolonged bodily contact.

✅ High Strength & Durability – Withstands repeated sterilization and mechanical stress.

✅ Cost-Effective Production – Lower per-unit costs for high-volume manufacturing.

✅ Design Flexibility – Allows integration of multiple features into a single component.

Medical Applications of Die Casting

1. Surgical Instruments

Examples: Scalpel handles, forceps, clamps

Benefits: Lightweight, ergonomic, corrosion-resistant

2. Diagnostic & Imaging Equipment

Examples: MRI components, X-ray machine parts, ultrasound transducers

Benefits: High dimensional accuracy, EMI/RFI shielding

3. Implants & Prosthetics

Examples: Bone screws, dental implants, joint replacements

Benefits: Biocompatible, long-term durability

4. Portable Medical Devices

Examples: Insulin pumps, nebulizers, wearable monitors

Benefits: Lightweight (magnesium alloys), compact design

5. Dental Tools & Orthodontics

Examples: Drill handpieces, braces components

Benefits: High precision, smooth surfaces for patient comfort

Die casting is a vital manufacturing method in the medical industry, offering unmatched precision, material versatility, and cost efficiency. Its ability to produce sterile, biocompatible, and high-performance components makes it indispensable for modern healthcare technology. As medical devices continue to advance in complexity, die casting will play an increasingly critical role in their development.

Die casting is an advanced manufacturing process increasingly used in the medical industry to produce high-precision, sterile, and durable components. The process involves injecting molten metal—typically aluminum, zinc, or magnesium alloys—into precision-engineered steel molds under high pressure. This method ensures exceptional accuracy, smooth surface finishes, and structural integrity, making it ideal for medical instruments, implants, and diagnostic equipment.

Why Die Casting is Used in Medical Applications?

Medical devices require:

✔ High Precision – Tight tolerances for reliable performance

✔ Biocompatibility – Safe for contact with human tissue

✔ Sterilizability – Resistance to autoclaving and chemical cleaning

✔ Durability – Long-lasting performance in demanding environments

Die casting meets these demands while offering cost-efficiency and scalability for mass production.

Common Medical Die Casting Materials

1. Aluminum Alloys (e.g., A380, A360)

Advantages: Lightweight, corrosion-resistant, excellent thermal conductivity

Applications: Surgical instruments, imaging equipment housings, prosthetics

2. Zinc Alloys (e.g., Zamak 3, Zamak 5)

Advantages: High dimensional stability, smooth surface finish, biocompatibility

Applications: Dental tools, syringe components, orthopedic devices

3. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Ultra-lightweight, excellent strength-to-weight ratio, MRI compatibility

Applications: Portable medical devices, surgical robots, implantable components

Key Advantages of Die Casting in Medical Manufacturing

✅ Superior Precision – Produces complex geometries with tight tolerances (±0.005 inches).

✅ Smooth Surface Finish – Reduces bacterial adhesion and simplifies sterilization.

✅ Biocompatibility – Suitable for implants and devices in prolonged bodily contact.

✅ High Strength & Durability – Withstands repeated sterilization and mechanical stress.

✅ Cost-Effective Production – Lower per-unit costs for high-volume manufacturing.

✅ Design Flexibility – Allows integration of multiple features into a single component.

Medical Applications of Die Casting

1. Surgical Instruments

Examples: Scalpel handles, forceps, clamps

Benefits: Lightweight, ergonomic, corrosion-resistant

2. Diagnostic & Imaging Equipment

Examples: MRI components, X-ray machine parts, ultrasound transducers

Benefits: High dimensional accuracy, EMI/RFI shielding

3. Implants & Prosthetics

Examples: Bone screws, dental implants, joint replacements

Benefits: Biocompatible, long-term durability

4. Portable Medical Devices

Examples: Insulin pumps, nebulizers, wearable monitors

Benefits: Lightweight (magnesium alloys), compact design

5. Dental Tools & Orthodontics

Examples: Drill handpieces, braces components

Benefits: High precision, smooth surfaces for patient comfort

Die casting is a vital manufacturing method in the medical industry, offering unmatched precision, material versatility, and cost efficiency. Its ability to produce sterile, biocompatible, and high-performance components makes it indispensable for modern healthcare technology. As medical devices continue to advance in complexity, die casting will play an increasingly critical role in their development.