English ![]()

No. 7, Tianyang 6th Road, Dongfang Community, Songgang Street, Bao'an District, Shenzhen, Guangdong, China(518100)

| Availability: | |

|---|---|

| Quantity: | |

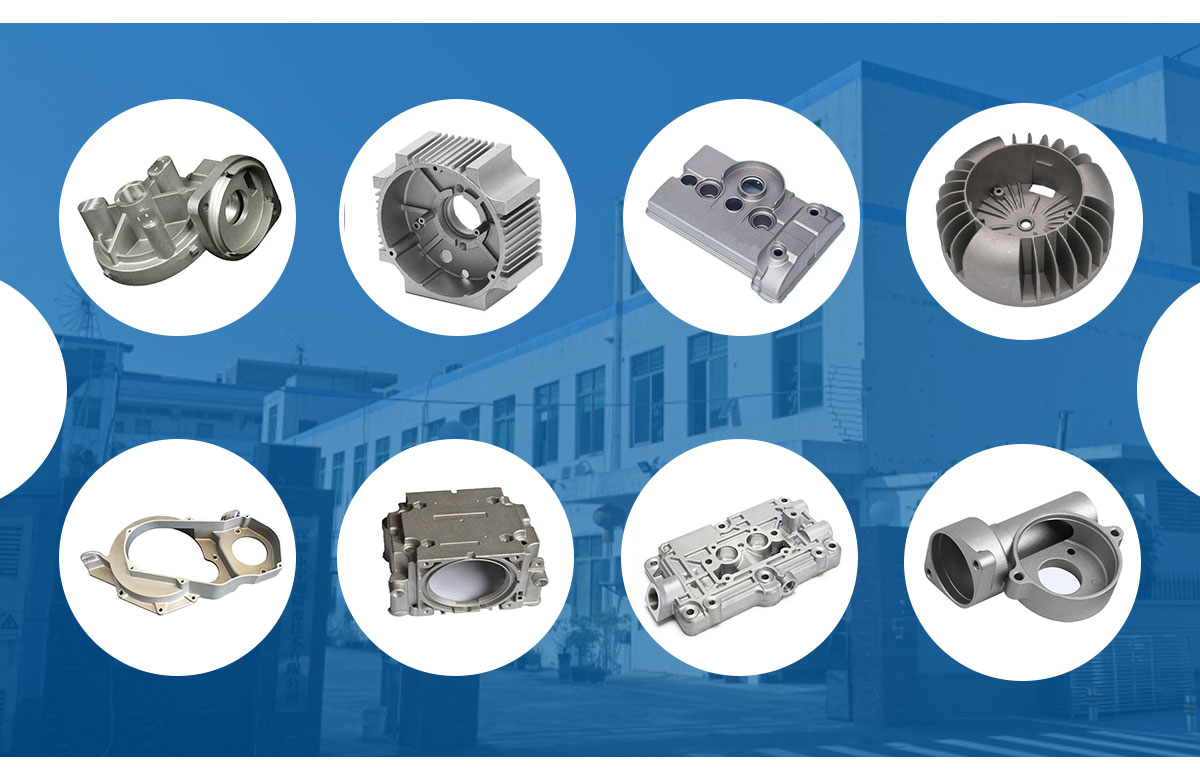

Die casting is a critical manufacturing process in the aerospace industry, where precision, strength, and lightweight components are essential. The process involves injecting molten metal—typically aluminum, magnesium, or zinc alloys—into high-strength steel molds under high pressure. This method ensures the production of complex, high-performance parts with excellent mechanical properties and tight tolerances, making it ideal for aerospace applications.

Why Die Casting is Used in Aerospace?

Aerospace components demand:

✔ Lightweight materials to improve fuel efficiency

✔ High strength-to-weight ratio for structural integrity

✔ Corrosion resistance for durability in harsh environments

✔ Precision manufacturing to meet strict aviation standards

Die casting meets these requirements efficiently, reducing material waste and machining time compared to traditional manufacturing methods.

Common Aerospace Die Casting Materials

1. Aluminum Alloys (e.g., A380, A356)

Advantages: Lightweight, corrosion-resistant, good thermal conductivity

Applications: Aircraft engine components, structural brackets, housings

2. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Extremely lightweight (35% lighter than aluminum), excellent vibration damping

Applications: Seat frames, gearbox housings, electronic enclosures

3. Zinc Alloys (e.g., ZA-8, Zamak alloys)

Advantages: High strength, excellent surface finish, good impact resistance

Applications: Avionics components, connectors, small structural parts

Key Advantages of Die Casting in Aerospace

✅ Weight Reduction – Critical for fuel efficiency and payload optimization.

✅ High Strength & Durability – Die-cast parts withstand extreme stress and temperature variations.

✅ Complex Geometries – Allows integrated designs, reducing assembly parts.

✅ Cost Efficiency – Lower machining needs and faster production than CNC or forging.

✅ Superior Surface Finish – Reduces post-processing and improves aerodynamics.

Aerospace Applications of Die Casting

1. Engine & Turbine Components

Examples: Compressor housings, turbine blades, fuel system parts

Benefits: Heat resistance, reduced weight, high precision

2. Structural Components

Examples: Wing brackets, landing gear parts, fuselage frames

Benefits: High load-bearing capacity, fatigue resistance

3. Avionics & Electrical Systems

Examples: Sensor housings, communication device casings

Benefits: EMI shielding, corrosion resistance

4. Interior & Cabin Components

Examples: Seat frames, overhead bin mechanisms

Benefits: Lightweight, fire-resistant properties

Die casting plays a vital role in aerospace manufacturing by providing lightweight, high-strength, and cost-effective solutions. Its ability to produce near-net-shape components with minimal waste makes it indispensable for modern aircraft and spacecraft design.

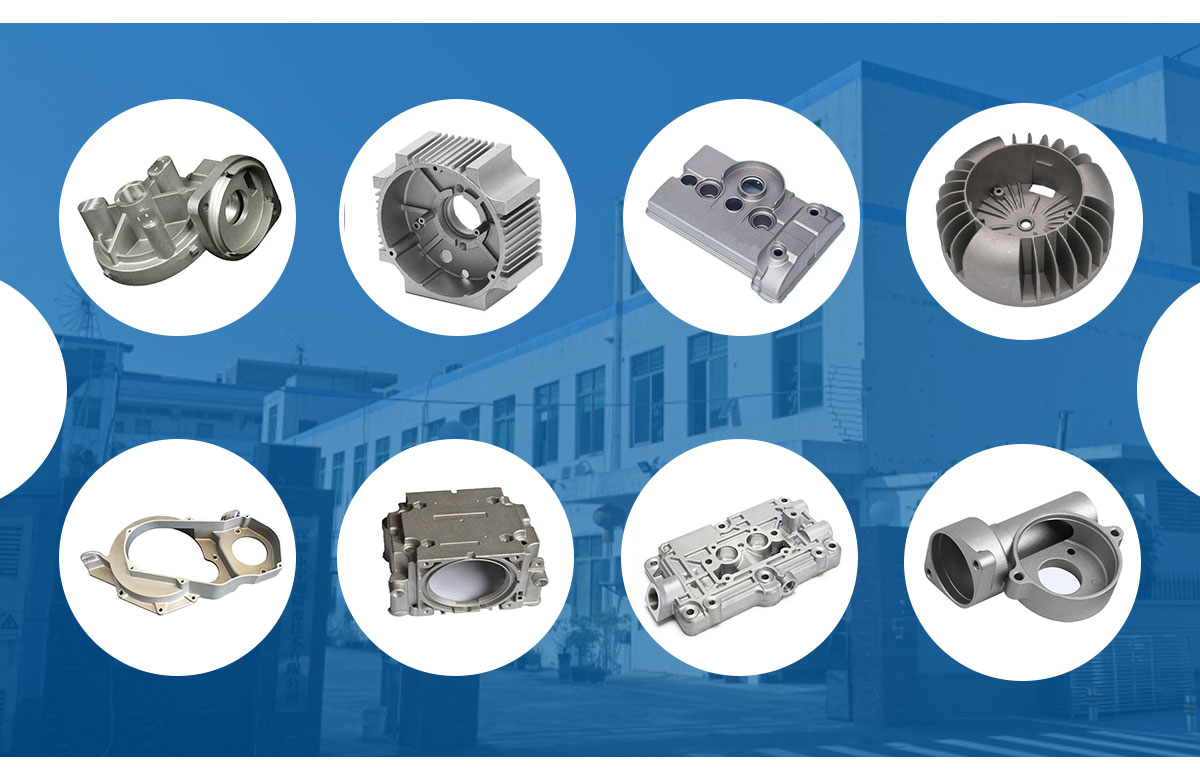

Die casting is a critical manufacturing process in the aerospace industry, where precision, strength, and lightweight components are essential. The process involves injecting molten metal—typically aluminum, magnesium, or zinc alloys—into high-strength steel molds under high pressure. This method ensures the production of complex, high-performance parts with excellent mechanical properties and tight tolerances, making it ideal for aerospace applications.

Why Die Casting is Used in Aerospace?

Aerospace components demand:

✔ Lightweight materials to improve fuel efficiency

✔ High strength-to-weight ratio for structural integrity

✔ Corrosion resistance for durability in harsh environments

✔ Precision manufacturing to meet strict aviation standards

Die casting meets these requirements efficiently, reducing material waste and machining time compared to traditional manufacturing methods.

Common Aerospace Die Casting Materials

1. Aluminum Alloys (e.g., A380, A356)

Advantages: Lightweight, corrosion-resistant, good thermal conductivity

Applications: Aircraft engine components, structural brackets, housings

2. Magnesium Alloys (e.g., AZ91D, AM60B)

Advantages: Extremely lightweight (35% lighter than aluminum), excellent vibration damping

Applications: Seat frames, gearbox housings, electronic enclosures

3. Zinc Alloys (e.g., ZA-8, Zamak alloys)

Advantages: High strength, excellent surface finish, good impact resistance

Applications: Avionics components, connectors, small structural parts

Key Advantages of Die Casting in Aerospace

✅ Weight Reduction – Critical for fuel efficiency and payload optimization.

✅ High Strength & Durability – Die-cast parts withstand extreme stress and temperature variations.

✅ Complex Geometries – Allows integrated designs, reducing assembly parts.

✅ Cost Efficiency – Lower machining needs and faster production than CNC or forging.

✅ Superior Surface Finish – Reduces post-processing and improves aerodynamics.

Aerospace Applications of Die Casting

1. Engine & Turbine Components

Examples: Compressor housings, turbine blades, fuel system parts

Benefits: Heat resistance, reduced weight, high precision

2. Structural Components

Examples: Wing brackets, landing gear parts, fuselage frames

Benefits: High load-bearing capacity, fatigue resistance

3. Avionics & Electrical Systems

Examples: Sensor housings, communication device casings

Benefits: EMI shielding, corrosion resistance

4. Interior & Cabin Components

Examples: Seat frames, overhead bin mechanisms

Benefits: Lightweight, fire-resistant properties

Die casting plays a vital role in aerospace manufacturing by providing lightweight, high-strength, and cost-effective solutions. Its ability to produce near-net-shape components with minimal waste makes it indispensable for modern aircraft and spacecraft design.